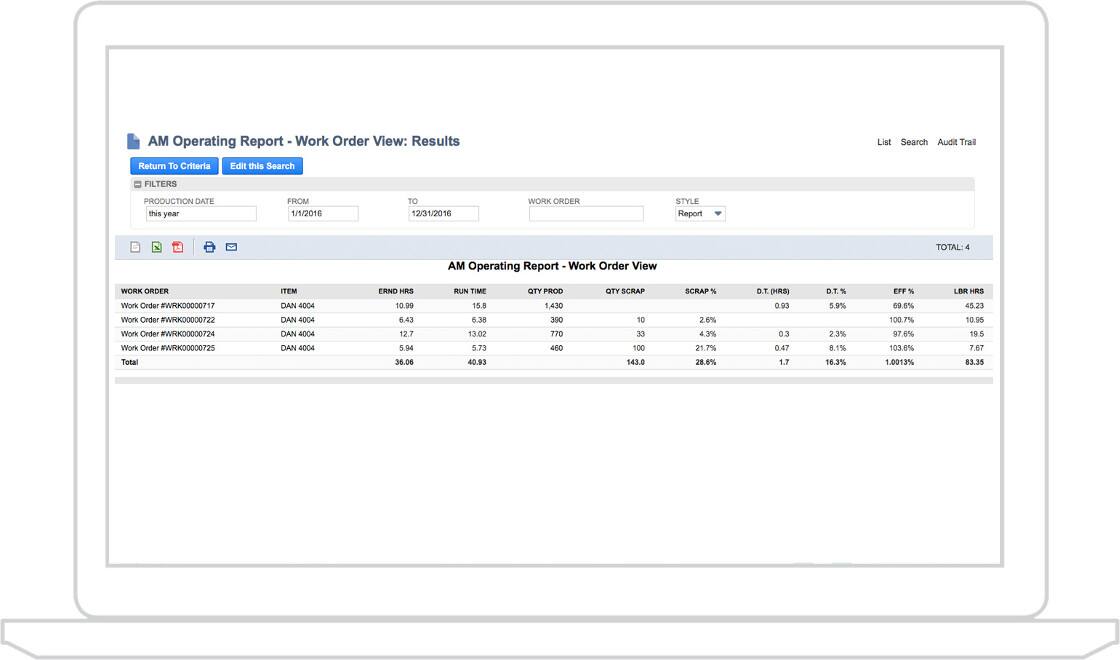

Sfcs typically calculate work in process based on a percentage of completion for each order and operation that are useful in inventory valuations and materials.

Shop floor control definition.

The definition of shop floor control sfc shopfloor is a state of the art software application for production tracking that runs across multiple platforms on any device computers tablets phones and tvs to name a few.

They include the procedures used to evaluate current resource status and the update of labor machine hour and other associated information as required to support the overall planning.

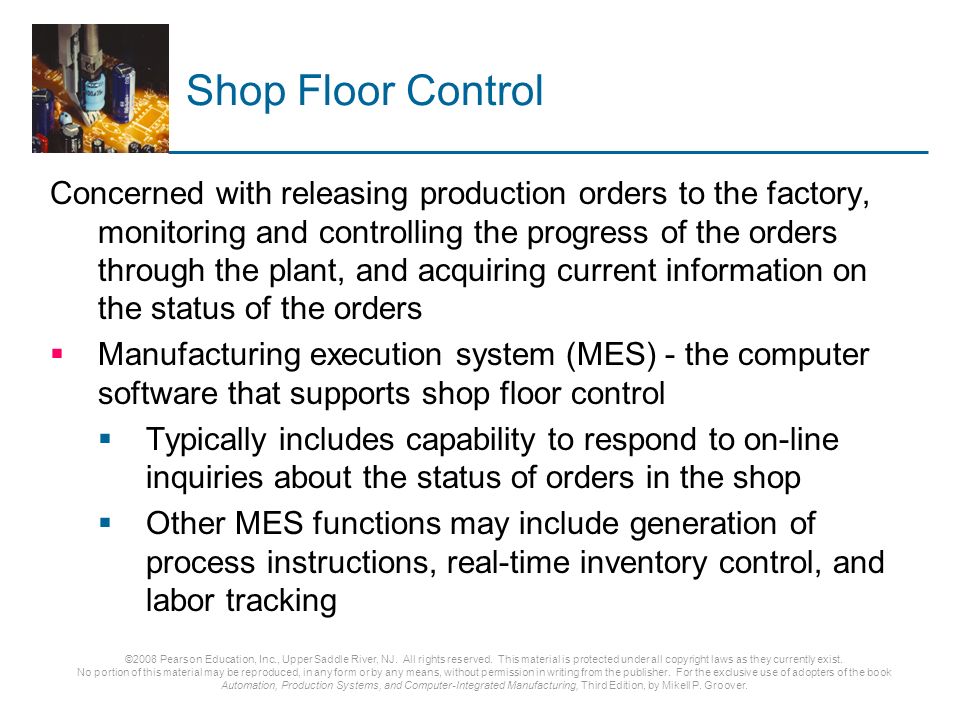

This technology allows supervisors managers and workers to receive real time information and notifications regarding their manufacturing operations and work in.

It includes the procedures to evaluate current resource status labor machine usage and other information required to support the overall planning scheduling and costing systems related to shop floor operation.

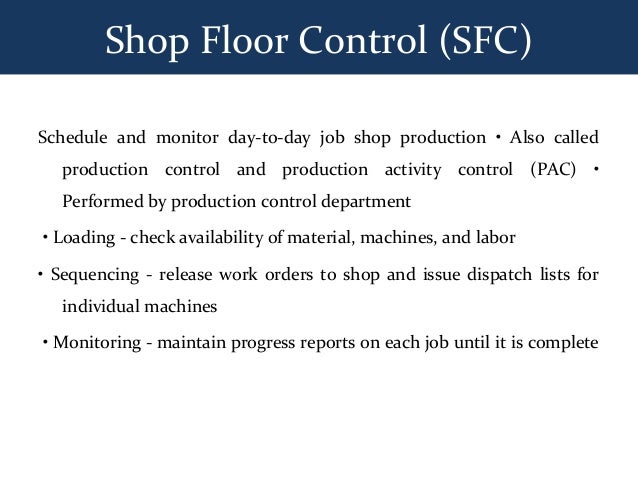

Shop floor control sfc refers to a set of tools and techniques that are used to track monitor and supervise manufacturing people processes and materials on the production floor.

Shop floor control delivers the ultimate solution to running a manufacturing plant profitably by allowing you to accurately predict production costs based on estimated material labor and overhead and allowing you to analyze actual.

This type of tool is a major part of business process automation which industrial businesses are using to streamline workflows promote efficiency and improve revenue cycles.

It allows you to manage and track manufacturing work orders processes and rate schedules.

Shop floor control comprises the methods and systems to prioritize track and report against production orders and schedules.

That percentage of work in process is useful for resource planning inventory evaluations 1 and supervisor and operator.

Shop floor control sfc systems are systems for managing the various components of the manufacturing process.

Definition of shop floor control shop floor control are methods and systems used to prioritize track and report against production orders and schedules.

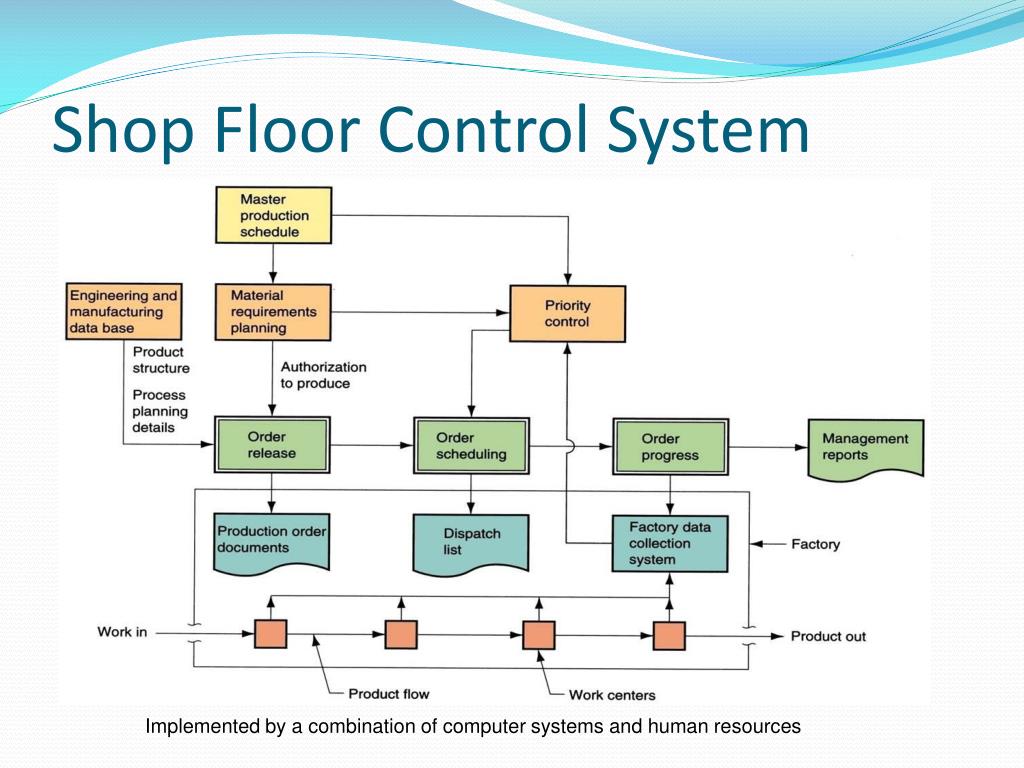

The jd edwards world shop floor control system implements the material plan by managing the flow of materials inside the plant.

An effectively managed shop floor control system serves as a mediator between production control and the shop floor.

This technology allows supervisors managers and workers to receive real time information and notifications regarding.

Shop floor control sfc is a software system of methods and tools that are used to track schedule and report on the progress of work in a manufacturing plant shop floor control systems generally evaluate the portion of an order or operation that has been completed.

Clear definition of each production operation is the key to effective manufacturing business management.